| ||||

> Jensen Healey & Jensen GT Tech > Ignition > Distributor timing and cam belt on a custom high power engine |

| ||||

> Jensen Healey & Jensen GT Tech > Ignition > Distributor timing and cam belt on a custom high power engine |

| Moderated by: Greg Fletcher | Page:   1 2 3 1 2 3   |

|

|||||||||||||

| Distributor timing and cam belt on a custom high power engine | Rate Topic |

| Author | Post |

|---|

| Posted: 02-12-2020 09:37 pm |

|

21st Post |

|

discogodfather Member

|

Tom Bradley wrote:

Interesting, I thought the exact same thing in terms of that spiral cut- some way to push oil in the opposite direction. The dizzy is marked with a "74" on there and I first thought it might be one of the earlier units without a shaft seal, but I have no idea. I did manage to find a source for the actual seals used in the proper "lotus" version from a source in the UK. Looks like a simple lip seal. This is for the 43/45: https://www.sjsportscars.com/parts-and-accessories/SJ754.htm

|

||||||||||||||

| |||||||||||||||

| Posted: 02-13-2020 02:59 am |

|

22nd Post |

|

Tom Bradley Member

|

Replacements for the internal distributor seal has come up numerous times on this forum. Here is the link to one of them: http://www.jensenhealey.com/forums/view_topic.php?id=2134&forum_id=5 (look at post #2) I used the recommended one from Mcmaster Carr a couple of years ago and have had no problems so far. I had to press the steel bearing down a bit to install it in the opening but did not have any problems with that. Getting the distributor apart to see how the shaft was designed was much harder.

|

|||||||||||||

| ||||||||||||||

| Posted: 02-13-2020 05:27 pm |

|

23rd Post |

|

Esprit2 Member

|

discogodfather wrote:Just picked up on this difference after re-reading Tim's explanation- there is a black metal ring on the bottom of the floor of the distributor housing. It's not much of a seal though, it looks to be worn well in.All Lucas distributors have a rubber O-ring around the outside of the long, slender shaft housing, where it slips into the engine. ONLY the Lotus/ J-H distributors have an internal rubber lip seal. The standard Lucas distributor has steel bushings for the shaft, one at each end of the long shaft housing. The top one is pushed in flush with the surrounding floor of the upper 'head' part of the housing. If a seal is present, then the upper bushing was simply pushed about 4-5 mm deeper into the housing to make room for the rubber seal. Then the seal was pushed in until flush with the surrounding floor... or a wee bit below flush. If you see a rubber seal, then the distributor is configured for a Lotus/ J-H engine. If you see the edge of a steel bushing, then it's not. The spiral on the shaft is there to act as a 'pump' to keep oil from migrating toward the head of the distributor. It's effective when the distributor is mounted vertically, or nearly so. However, it's NOT effective when the distributor is mounted horizontally, and oil will leak out via the head of the distributor. So Lucas added the rubber lip seal specifically for Lotus/ J-h applications... no others. In North America, Delta Motorsports, JAE, and Dave Bean Engineering all stock the seal for Lucas' Lotus/ J-H distributors. The same seal also fits the Pertronix and 123 distributors that are close clones of Lucas. Source: GACO IND49248 (Lucas OEM Seal). Source: Chicago Rawhide CR4912 (exact replacement). Source: Transcom TCM 13x19x3VG (nearest metric size). Source: McMaster-Carr 9505K17 (different seal style... but works). In the GACO IND49248 part number, IN = INternal, and D = Distributor. It's made for the purpose. GACO Seals Website: https://gacoseals.co.uk/ GACO Seals Directory: https://gacoseals.co.uk/gaco-special-oil-seals-directory.html GACO = George Angus & COmpany (Oil Seals). Regards, Tim Engel Last edited on 02-13-2020 05:29 pm by Esprit2 |

||||||||||||||

| |||||||||||||||

| Posted: 02-13-2020 05:55 pm |

|

24th Post |

|

discogodfather Member

|

Thanks Tim and Tom, ordered some seals and am going to install them. I also will attempt to install one on the newer 43D copy, even though it needs some machining in the lather. Thanks, Chris

|

|||||||||||||

| ||||||||||||||

| Posted: 02-13-2020 06:55 pm |

|

25th Post |

|

Esprit2 Member

|

Chris, Are you sure that machining is required? I'm not familiar with which 43D copy you have, but in all the Lucas and Pertronix/ 123 clones I've seen, the shaft bore is straight, no steps. Installing a seal only requires that the top bushing be pushed 4-5 mm deeper into the bore to make room for a seal. Regards, Tim Engel

|

||||||||||||||

| |||||||||||||||

| Posted: 02-13-2020 07:37 pm |

|

26th Post |

|

discogodfather Member

|

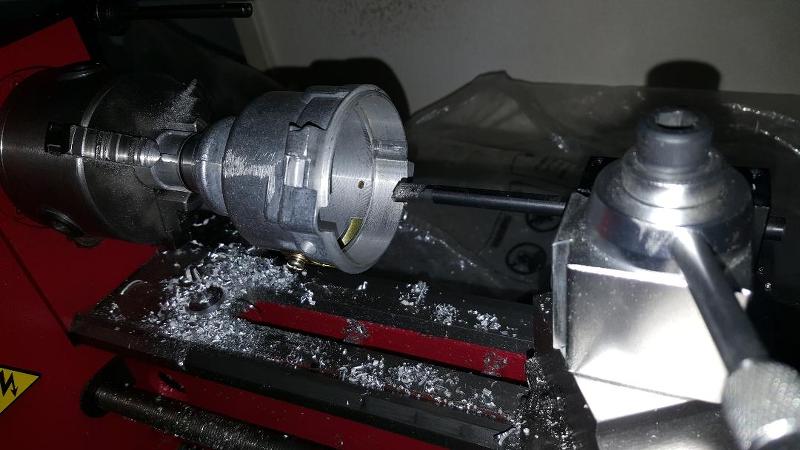

Esprit2 wrote:Chris, The new 43D I have has much smaller bushing sizes and a thicker aluminum shaft. The seal seems to need slight over .75" diameter hole to sit in, so I can push the bearing in and then cut a .75" seat for it. On the right you see the Lucas- the "steel ring" that was sitting at the top turned out to be a nearly petrified rubber seal- it was so hard I mistook it as steel. Removed it with ease, waiting on my new seals to come in. Great advice Tim! At the rate I am going I will have two viable distributors to test.

|

|||||||||||||

| ||||||||||||||

| Posted: 02-13-2020 08:43 pm |

|

27th Post |

|

discogodfather Member

|

Was able to cut a nice 4mm deep by around 17.5mm diameter recess for the seal in in the new 43D housing using a small lathe and a boring bar. Came out nice! I might consider doing this to a Flamethrower or 123 in the future, but for now I am concentrating on a stock unit rebuilt and comparing it to the new 43D. I know the advance curves will be totally different. The old Lucas 25D has a 11 degrees stamped on the advance arm. That seemed a bit odd, been reading 13 is stock?

|

||||||||||||||

| |||||||||||||||

| Posted: 02-13-2020 10:36 pm |

|

28th Post |

|

Tom Bradley Member

|

Wow, you have some nice equipment available and know how to use it. I am envious. Here is the distributor advance spec from the JH shop manual. I did not notice before, but the advance for the 45D distributor is significantly different from the 25D. Mine is also stamped with 11 degrees, but when I check the advance with a timing light I get the spec'd 17 degrees from 1000 to 2500 RPM. Attachment: JH5 Distributor advance.jpg (Downloaded 132 times)

|

|||||||||||||

| ||||||||||||||

| Posted: 02-16-2020 07:37 pm |

|

29th Post |

|

Esprit2 Member

|

Well, I'll have to defer to what you see in your hands, but the original 43/45 Lucas distributors used the same seals as the earlier 23/25 distributors, and the Pertronix/ 123 clones mimic the 43/45. With them, all that was required was to push the top steel bushing 4-5 mm deeper into the straight bore in order to make room for the seal. I'm impressed by your photos of all your machine work, I'm just surprised that it's necessary. *~*~*~* A friend and I recently rebuilt the 45DM4 out of this 1984 Turbo Esprit's 910, the stock GACO seal was present, and it's the same as the one in his 1977 S1 Esprit's 25D4. So now I'm quite curious about your need to machine the bore. Regards, Tim Engel Last edited on 05-16-2020 10:29 pm by Esprit2 |

||||||||||||||

| |||||||||||||||

| Posted: 02-20-2020 11:49 pm |

|

30th Post |

|

redracer Member

|

The very early J-H distributors did NOT have an internal oil seal in(later ones did); for those like that I had worked on, I knocked the upper steel bushing down (as Tim has said) and installed a slightly thicker-than-original "rubber"(neoprene) seal; part # 4702 for both CR & SKF. The dimensions are: 12mmX19mmX5mm(original was 3 mm; someone has previously written 1/2" inner diameter, but that is TOO LARGE). I use Permatex #2 on the outer shaft housing for extra peace-of-mind! btw; if you ever refer your dizzy to a "rebuild" house, the 5 digit # on the outside of the dizzy is incorrect in that these numbers refer to a dizzy spinning in a CCW direction, whereas ours spin CW. You may have noticed the arrow in the top of the dizzy has been filed off just for that reason! hope this helps, bruce

|

|||||||||||||

| ||||||||||||||

| Posted: 04-11-2020 05:44 am |

|

31st Post |

|

discogodfather Member

|

Esprit2 wrote:Disco, Was again experiencing tuning problems at high RPM and decided to take the head off, it actually came out way easier than I thought. I phoned and talked to Barry today and he's a great guy. I really think he might have built this engine 20 years ago, he could not remember but it's pretty sure upon looking into it for the first time. The heads were ported, the work is immaculate, and it has the high comp J&E machined pistons. Liners look great and all it took was a rag and a wipe down and they look new. I can still see some of the crosshatch on the liners. Again the mystery cams bothered me because I could not find any marks. Barry said to look behind the thrust plate and sure enough, there was "104" imprinted on both. So now the mystery is over, I can time them! I was about to send them off for a set of new 104's so this phone call saved me $300. I'll also be able to tell how badly my timing was off for the last 2-3k miles, so that will be enlightening. Thanks for the recommendation Tim! When I bull these valves and inspect the seats and there is any damage at all I will be sending them over to Barry for some work.

|

||||||||||||||

| |||||||||||||||

| Posted: 04-11-2020 07:50 pm |

|

32nd Post |

|

Esprit2 Member

|

Disco, I'm not so sure about the cam being a Lotus 104. A 'Lotus' 104 cam had 44444444... stamped all around the exposed bit of shank between the front of the cam carrier and the back of the pulley. Many cam grinders produced '104' cams that did not match the Lotus 104 specs, and "104" as a name was used about like "3/4 Race" was used for American V8 cams. L-o-n-g ago, I bought a pair of "104" cams on eBay, and they are NOT Lotus 104 cams. They have a much hotter profile, and they're just sitting on a shelf because I don't know what they are or how to time them. Like yours, they were stamped with "104" on the back end. So, I called Delta Motorsports, described the markings, and they said it wasn't their 104 cam. So I called Delta Cams, and they said it wasn't theirs. I never did find out whose '104' cams they were, but the lobe profile does not match the genuine Lotus 104 cams I already had on hand. Lotus 104 Cam Specs: 0.415" Lift (0.410/ 0.415"/ 0.420", depending upon who you ask). 32° .Int Opens, BTDC 60° .Int Closes ABDC 60° .Exh Opens, BBDC 32° .Exh Closes ATDC 64° .Overlap, Degrees 272° Duration, Degrees 104° MOP, Degrees On Delta Motorsports website, they list their "104" cam as Part No BLL-104, 280° Duration, 0.420" lift. Good luck, Tim Engel

|

|||||||||||||

| ||||||||||||||

| Posted: 04-11-2020 08:07 pm |

|

33rd Post |

|

Esprit2 Member

|

Sorry about the redundancy. It seems I posted something similar back in February. Tim

|

||||||||||||||

| |||||||||||||||

| Posted: 04-11-2020 08:52 pm |

|

34th Post |

|

discogodfather Member

|

Esprit2 wrote:

Ah, the mystery deepens, I'll send them with the head to Barry to try and make some sense out of it. Profiles are very sharp indeed. Intake seems to be marked DB3-104? Could that be Dave Bean?

|

|||||||||||||

| ||||||||||||||

| Posted: 04-11-2020 10:49 pm |

|

35th Post |

|

redracer Member

|

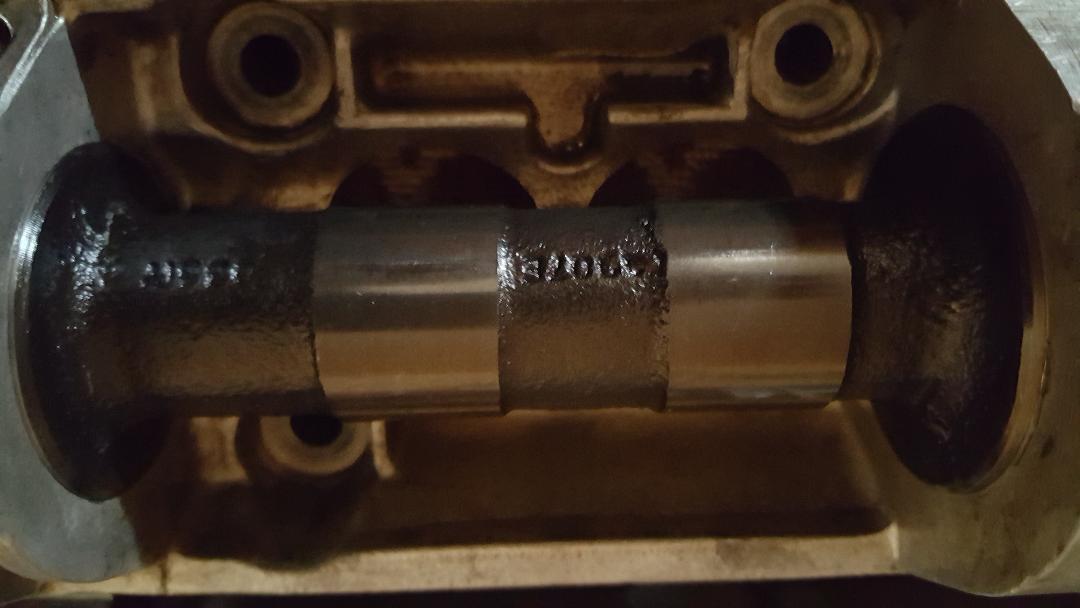

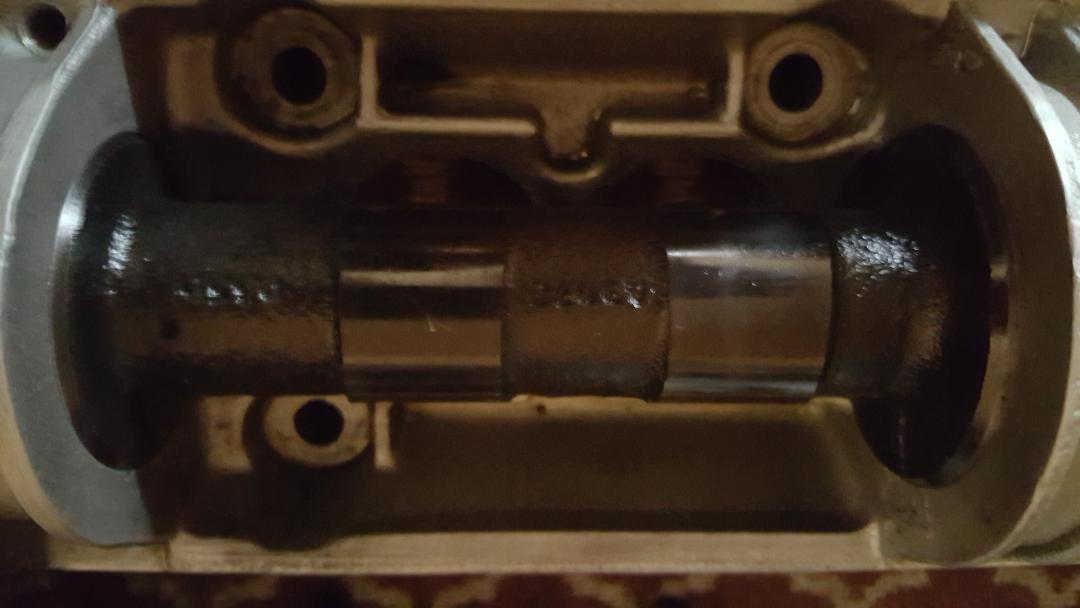

Very interesting; you have a '73 cam housing on the right(the bearing sizes were 0.001" smaller than the later housings.) There used to be galling on those earlier housings which was really caused by lack of oil(leaking from the cam covers) rather than too tight a clearance.

|

||||||||||||||

| |||||||||||||||

| Posted: 04-11-2020 11:15 pm |

|

36th Post |

|

discogodfather Member

|

redracer wrote:Very interesting; you have a '73 cam housing on the right(the bearing sizes were 0.001" smaller than the later housings.) I was wondering about that difference, assumed it was supposed to be like that. I'll see if I can pick up a newer one for the rebuild. Are they the same otherwise in terms of intake and exhaust?

|

|||||||||||||

| ||||||||||||||

| Posted: 04-12-2020 12:16 am |

|

37th Post |

|

redracer Member

|

Yes, they're the same. Again, the earlier cam housings were 0.001" smaller on each of the 5 cam housing "bearing" surfaces.

|

||||||||||||||

| |||||||||||||||

| Posted: 04-12-2020 04:46 am |

|

38th Post |

|

discogodfather Member

|

redracer wrote:Yes, they're the same. Again, the earlier cam housings were 0.001" smaller on each of the 5 cam housing "bearing" surfaces. Just to be safe, because I typically get everything backwards, the housing with the cutouts on the central hoops is the earlier version with the smaller bearing surfaces and the one with the filled in and a kind of nipple sticking up is the later style with the looser tolerances?

|

|||||||||||||

| ||||||||||||||

| Posted: 04-12-2020 12:38 pm |

|

39th Post |

|

redracer Member

|

correct; ypur last photo is the earlier housing. It has the "ribs" slightly hollowed/grooved out, whereas the later ones have the little nib sticking up in the middle of the ribs.

|

||||||||||||||

| |||||||||||||||

| Posted: 04-13-2020 05:57 am |

|

40th Post |

|

Esprit2 Member

|

discogodfather wrote:Intake seems to be marked DB3-104? Could that be Dave Bean?I've never seen the DB3-104 designation before... which means nothing. The only Dave Bean cam designation of which I'm aware is BLL-104. That's the same designation that Delta Motorsports uses. BLL - "Bean Lotus Leeslay", and I have no idea what or who Leeslay is. Regards, Tim Engel Last edited on 05-16-2020 10:52 pm by Esprit2 |

|||||||||||||

| ||||||||||||||

| Current time is 09:54 pm | Page:   1 2 3 1 2 3   |

| > Jensen Healey & Jensen GT Tech > Ignition > Distributor timing and cam belt on a custom high power engine | Top |