Changing ‘74 Jensen

Healey Timing Belt Tensioner Bearings

Something Every J-H

Owner May Want To Know!

By Greg Fletcher

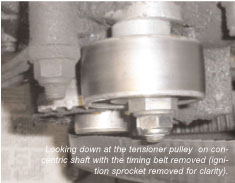

The concentric pulley

tensioner adjuster should have new bearings installed on a regular basis.

My rule of thumb is every other timing belt change. The stock timing belt

must be changed every 18,000 miles to avoid breakage and a really messed up

engine. A broken belt will, of course, bend all your nice valves causing much

trouble and creating great expense.

I’m using the up-rated half-moon timing belt and adjustable pulley gears

(about $300 from Dave Bean Engineering) so I can go more like 40,000 - 50,000

miles between belt changes, a great time saver! I’ve only recently realized

it’s been a good 70,000 miles since I’ve changed the tensioner bearings.

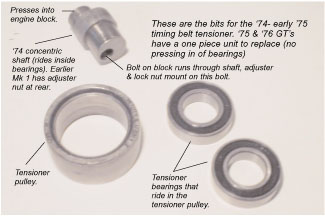

Although I have a ‘73, my current the engine is from a ‘74, otherwise

the adjuster above would look a bit different than the one shown in the

photo above.

You should always plan on a timing belt change with the replacement bearings

since the outer crank fan belt pulley must be removed to pull off the concentric

pulley (and bearings) above it.

The whole process is NBD (No Big Deal) with the only requirements being some

modest tools, timing light, a drift, a good bench vise to press off the old

bearings and press on the new ones and a few hours of your time.

Tools needed

Basic 1/2” drive

socket set, including a 19mm socket for the crankshaft bolt & a 1 3/4”

or 44-45mm round object used a drift.

- 1/2’ drive torque

wrench

- Bench vise

- One set (two) bearings

($20 from Delta Motorsports)- ‘75 & ‘76 use a one-piece pulley

unit ($75 from Delta Motorsports)

- New Nylock locknut

for adjuster

- Timing belt (about

$30)

- 22mm open end wrench

or crescent wrench for tensioner adjuster

- Mark I ‘72 &

‘73 JH’s need the special Jensen rear adjusting tensioner wrench

or convert to ‘74 style adjuster (needs some machining or this)

- Rubber or similar mallet

- Timing light to check

timing

- Anti-seize compound

Top Dead Center

Remove the battery negative cable and the coil lead for safety. Turn the engine

over until the gears line up (you may need to turn two revolutions for the

cam gears to line up) at Top Dead Center (TDC). If in doubt you can remove

the cam bolts & washers to see where the keyways are located. I would

advise anyone to never remove the timing belt without the engine at TDC. If

any gears are moved, it will be difficult to see and even harder to set back

properly.

At TDC, before I get too deep into anything, I always loosen the crankshaft

bolt. Put the car in gear and apply the hand brake. This bolt should be torqued

to 58-60 ft lbs, so a 19mm wrench and a rubber mallet should break it loose

with a few blows. If not, the bolt has been over torqued and you will need

to figure out how to loosen it before you proceed. Often, a liberal application

of a firm mallet will eventually work. On occasion, an impact gun is the only

thing that will remove it (presumably as this is how it got that way to

begin with).

An electric impact gun often works for the home mechanic. At this point you

would need to remove the radiator to gain access to the bolt from the front

(add an additional vino to the rating for that).

With the bolt slightly lose, make sure the engine is still at TDC, or tighten

a bit and readjust.

Use you mallet to tap the fan belt pulley forward and remove so you’ll

have access to the timing belt at the crankshaft.

Use a 22mm open end wrench to loosen the concentric adjuster (pull the wrench

toward you to loosen, away to tighten). The belt should be loose and you can

now pull it forward and off of the gear pulleys.

Do not move the cams in relation to the crankshaft. If doing a valve

adjustment you would rotate the crankshaft back (counter clockwise) about

15 degrees to go down into the liners so the cams could move independently

and not contact the pistons. For changing a timing belt and tensioner bearings

it is sufficient to leave the crank and other pulleys as is.

With the outer crank pulley removed we can now remove the tensioner pulley

assemble from the engine. The concentric shaft that the pulley rides on is

a simple press fit into the block, and I just rotated the adjusting nut on

the front clockwise to move it forward. In a few minutes that is off the block

and we can now consider the bearings.

Once removed, I could tell immediately that the bearings were in a bad state.

They were very rough when spun and made most unpleasant noises. I did notice

the old ones were made in Japan and that the new bearings are now made in

the fine country of Rumania. This gave some cause for concern, but they seemed

smooth enough and were definitely a lot better than what I had now.

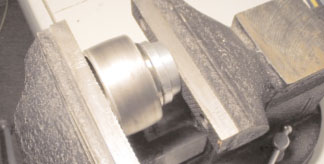

Pressing out the old bearings

The key here is finding the correct size socket(s) or other stout round implement

to act as an impromptu drift. To remove the concentric shaft, a 17mm socket

and two pieces of wood were all that

were needed.

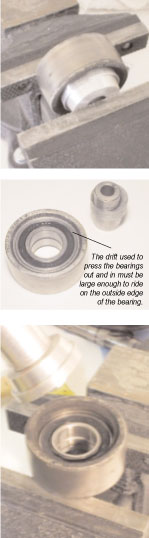

With the shaft removed I could deal with the bearings themselves. This proved

somewhat troublesome, and took a while before I found a drift that was exactly

the right size. When pressing out the old bearings and especially when pressing

new ones in, it’s quite important to have a drift that will ride on the

outside metal edge of the bearing and not crush the bearing sleeve inside.

You’ll need a suitable drift that measures 1 3/4” (44-45mm) in diameter.

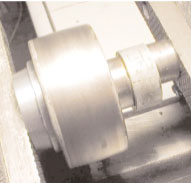

I started it in the vise (above), which will only press out about an 1/8”

and I then pounded the rest of the way with my drift on the vise (right)

It’s a simple matter to press the new ones in back in. I used the larger

drift to press in the two bearings in the vise and then, with the large drift

to hold the bearing in place on one side, put the concentric shaft in the

vise and tightened it up. The new bearings were all back together in a few minutes.

The tensioner assembly is pressed back on the block (use a dab of anti-seize

here) by turning the adjuster and pushing back and then tightening into place

with the lock nut (always use a new Nylock nut). The new timing belt is put

back on (I removed the upper radiator hose and slide it down and around the

fan for that since I didn’t feel like removing the radiator on this job).

Everything else is replaced the way it came off. The belt should be adjusted

for tension (when cold you should be able to depress the belt about an 1/8

inch between the ignition sprocket and intake cam. This will need an additional

tightening in a few weeks of driving. Throw on a new fan belt, install the

crank pulley and torque the crank bolt to 58-60 lbs with your torque wrench,

reattach the battery and coil lead & adjust the new belt and you should

be ready to go.

Start up the engine and check the timing, adjust as necessary. Be sure to

take a look at the belt in a week or so of regular driving and readjust as

needed. That’s it! New bearings, new timing belt, you’re good for

at least another 18,000 miles on the belt or in my case another 40,000 miles

and

about that long on the tensioner

bearings.