| Moderated by: Greg Fletcher | ||

| Author | Post | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

terryhowarth Member

|

i've read all the articles here on oil pumps, and really need a step by step photographic lesson to achieve a rebuild. Only purched car 5 weeks ago and Engine was allways slow on pressure pickup (1-2 minutes)so I changed oil and filter 2 days ago with non return filter and 20W 40 oil. pressure increased for 1 day, although still very slow to pick up and today drove for 5kms and noticed No pressure. My question, is oil too low a viscosity (thin) or am I in deep trouble? and in need of a new pump and are they available |

|||||||||

|

Greg Fletcher Administrator

|

I'd only use a traditional 20w50 oil in this engine, but I doubt that is the nature of your problem. I would also avoid running the engine with no oil pressure as that can result in catastrophic failure in a short time. Oil pressure should build up in a few seconds, 1-2 minutes indicates significant issues. On the 907, very poor oil pressure can be caused by wear on the main bearings, oil pump problems or even contamination in the oil pump relief valve in the oil pump housing as well as a broken or blocked oil pressure tube, so you'll have a number of things to investigate. The oil pump is a fairly simple arrangement. The inner and outer rotor are what create the pumping action. These run a tight clearance and significant mileage will make them sloppy, but not normally anything close to what you are describing. It's usually worth investigating the oil relief valve spring. I'd remove it, clean everything well and reinstall with a good quality moly lube. |

|||||||||

|

subwoofer Member

|

I'll be aiming for 5W-50 as a first stop, if oil pressure is highish at full temp I will go down to 5W-40 to reduce wear in the cooler Norwegian climate. Terry, are you sure you oil cooler hasn't clogged up? The oil in mine was so thick even diesel had a hard time passing. The oil cooler sandwich plate does NOT have a bypass mechanism, so if the cooler clogs up, you will have exactly 0 pressure. Before I started tearing things apart, I was seeing the same symptom as you. Mind you, I haven't put everything back together yet, so I can't tell what helps and what doesn't, but I am really contemplating swapping the sandwich plate for one with a thermostat. Those never close off the bypass stream completely. -- Joachim |

|||||||||

|

terryhowarth Member

|

Thanks for all the advice, I pulled cooler hoses off and blew out with compressor and found no blockage, then removed distributor and brass plug on top of oil pump, then pumped the relief valve? in and out a couple of dozen times and managed to get a few lumps of crap to squirt out. Reinstalled everything and low and behold 55lbs at above 1200 rpm and 20lbs at fast idle. It still however has a mind of its own and tends to drop to around 5-10 lbs at low idle. Have purchased a 2nd hand pump off a Lotus supplier in England and when it arrives I can have a go at a proper rebuild. Another thing I noticed was after removing plugs and HT lead from coil and turning engine over via starter motor was a click sound that really sounded like HT spark jumping, could this have been the relief valve operating or the distributor shorting internally? also don't like that stupid plastic oil pressure line to gauge, can it be replaced with an electric sender unit on motor and new electric pressure gauge and if so where would I source the parts? thanks for your help |

|||||||||

|

Greg Fletcher Administrator

|

That's very hopeful then. What you really must do however is completely remove the spring from the housing and clean it so that it SPOTLESS. The smallest bit of debris or silicon can restrict the travel and in turn effect your oil pressure (this happened to me once so I know all about this problem). You need to drive out the little pin in the side that positions the piston end and remove the spring. Use moly or graphite lube on it when putting it back in. |

|||||||||

|

terryhowarth Member

|

Ok Greg I will have a go at that, How? do I take pull the dizzie and the cone section off or do I have to remove the whole auxillary gizmo off the block? Terry |

|||||||||

|

Greg Fletcher Administrator

|

I had the entire housing on the bench when I did it, my guess is that it would considerably easier that way, but you may be able to remove the distributor and drive the pin out with a small punch. If you decide to remove the housing, you'll need to set the engine at TDC, loosen the timing belt and mark the bottom most position of the front of the ignition pulley. |

|||||||||

|

terryhowarth Member

|

thanks Greg, do you know of a web site that has an exploded view of the whole arrangement? I have seen a picture on the Delta site, but its not too good. Also where is the pin? do I access it from within dizzie hole or ? |

|||||||||

|

terryhowarth Member

|

Over weekend did two engine flushes and got pressure back to 50lbs, still takes ages to come up on start, pulled auxillary housing and as per Delta exploded view of oil pump I did not have the compression olive or the sealing plug installed. So I have gone no further with the pump untill I get a response from the forum. BTW the pump looks as if it may have been rebuilt at some stage not long ago as all new gaskets and gasget cement. Any thoughts? |

|||||||||

|

subwoofer Member

|

Any leak on the suction side of the pump will cause priming to take longer. I think you will find the missing parts at SJ Sportscars -- Joachim Last edited on 03-28-2010 09:14 pm by subwoofer |

|||||||||

|

907heaven Member

|

What year is your car? The slow oil pick up on early models was caused by the lack of an air bleed in the pump. On later models there is a very small hole 1.5mm (from memory) that bleeds air out of the pump on start up and allows the pump to prime much faster. My fist Healey used to take something like 40 seconds to make oil pressure after start up. There was a service bulletin from the factory on how to drill the Aux housing to alleviate the problem, I did the modification and oil pressure came up in a few seconds. The same thing can happen if the bleed hole gets clogged up. I'll bet your car doesn't have the drilling, if you are taking the aux hosuing off to work on the pump it is easy to do - but you need a long drill bit as the position of the hole is tucked down inside a hollow. Garry |

|||||||||

|

terryhowarth Member

|

thanks for the info Gary, my car is 13599 off the production line 5/9/73 and is classed as a 1974 Mk2, I have the auxilliary housing off and think my problem is the olive and nut not correctly sealing the pickup pipe. It looks as if it has been tampered with over the years and a section of copper pipe has been added for a quick fix, can you explain to me then exact position to look for the oil drilling? Do I need to pull the pump apart to drill or is it in an oil gallery on the side plate? thanks Terry |

|||||||||

|

907heaven Member

|

Hi Terry, watch the oil pipe - they tend to get "necked" or "pinched" where the nylon olive squeezes the pipe - if your pipe is pinched-in you stand no chance of getting an air tight seal. Copper won't be strong enough to resist being crushed. Remember to change the nylon olive for a new one. It needs torquing to 55lbs / ft. I am new to this forum; is it possible to post a photo? If so I can take a photo of a correctly drilled housing and post it up. Regards GARRY |

|||||||||

|

terryhowarth Member

|

Gary, i'm new on the forum as well and have no idea how to post pics, you can email me direct if you want at terryhowarth@netspace.net.au thanks Terry |

|||||||||

|

907heaven Member

|

Terry, Greg kindly explained how to post a photo, so here is one - I'll mail you some extra ones. GARRY Attachment: P1020257.JPG (Downloaded 187 times) |

|||||||||

|

terryhowarth Member

|

Garry, thanks for the pics, mine is drilled. I had a bit of a go at the pickup pipe yesterday and was able to move it up and down by hand, so that looks to be the reason for slow pressure pickup. I am going to have ago at using a plumbers copper pipe expansion die on it today and if that does not work, out comes the engine! thanks again to all Terry |

|||||||||

|

terryhowarth Member

|

Gary, I just found out the bleed hole was drilled in the wrong place and had been blocked up again, so I drilled a new hole in the pump, expanded the pipe and now 8 seconds to 55lbs at cold start up and almost immediate when hot. Will need a new clutch soon so I will pull the engine and do the job correctly. But at the moment I can enjoy it. thanks to all |

|||||||||

|

907heaven Member

|

Great Result Terry - takes the stress out of starting the engine! |

|||||||||

|

dmatth Member

|

Hi All I'm reviving this Oil pressure string instead of starting a new one just to keep the topic consolidated. Here's our situation: We removed engine to replace header pipe. While engine was out took the opportunity to clean engine, replace front and rear main seals, new cam cover gaskets, new timing belt and idler bearings. After we put everything back together the car started right up ran good and had good oil pressure (maybe even a bit better than before). Took the car down to the exhaust shop to have a flange attachment fabricated for the new header, about a 3 mile trip, no problem, drove home next day, no problem. My son took the car out a few days later and about 4 mi from home he said it started running rough, oil pressure dropped and the car died. Couldn't restart it. I went to meet him and did get the car to run rough briefly, but still no oil pressure. Towed car home. Car now starts fine but still no oil pressure. Read above string, pulled oil pump housing, gears look ok, cleaned out relief valve, blew out oil line to gauge, still no oil pressure. Removed oil cooler adapter and reinstalled filter (to remove clogged oil cooler from the equation) still no oil pressure. Now I'm thinking oil pickup pipe. My thoughts are that the rough running/stall and the loss of oil pressure were only some what related. We did have the engine on a stand and rotated around a bit (not upside down but sideways to clean off the bottom of the sump) and it's possible some debris in the carb may have jarred loose and cause the rough running/stall (as I said the car starts and runs fine now). Now I wonder if tilting the engine might have caused the pickup pipe to loosen and lose it's seal. Seem far fetched but I'm out of ideas. I have the factory parts catalog but it's not very clear on the relation between the pump housing and the pickup pipe. Does the pickup pipe come out with the aux housing as a unit? Any other ideas are appreciated, especially if it involves less work than pulling the aux housing. Thanks, Doug Last edited on 06-21-2011 04:47 am by dmatth |

|||||||||

|

subwoofer Member

|

dmatth wrote:Now I'm thinking oil pickup pipe. Unless it is really rotten nothing should come apart by tilting the engine. This is what a pickup in bad shape (but still working) looks like:  I have the factory parts catalog but it's not very clear on the relation between the pump housing and the pickup pipe. Does the pickup pipe come out with the aux housing as a unit? Nope. The pickup pipe is locked to the block with a rubber donut and a special nut. It goes out downwards. Any other ideas are appreciated, especially if it involves less work than pulling the aux housing. Thanks, Doug Idiot mode question: Is there enough oil on it? Have you actually checked? It is VERY easy to install the rear oil seal so that it leaks, then you may lose a quart of oil in 20 minutes of driving easily. I know from experience. -- Joachim |

|||||||||

|

dmatth Member

|

Yeah, plenty of oil. Our repairs were successful in reducing the amount of escaping oil. So if the Pickup pipe goes out downward is there really no way to check it without removing the engine/sump? Obviously there is some connection between the pickup pipe and the aux housing for the simple reason of supplying oil to the pump. If I remove the aux housing will I have access to the pickup pipe enough to see if I can draw oil up it? Is there any other simple gizmos like clips or such in the pump that could go wrong, without horrifying noise, but make the pump non-functional? Doug |

|||||||||

|

Greg Fletcher Administrator

|

Contamination in the oil relief spring (inside the auxiliary housing) can create a no-oil pressure situation. A very small piece of stray silicon sealer is enough to make that happen. |

|||||||||

|

subwoofer Member

|

The oil pump consists of a rotor pressed onto the shaft and secured with a circlip, an annulus piece and the housing. I have never actually heard a really failed one, but I have seen a picture where the annulus had broken into 5 pieces or so. I would imagine it to be noisy. Access to the top of the pickup pipe is easy once you have the aux housing off, the hole is 3/4" or so in diameter. To have a look at the pickup the sump must be dropped. I would not recommend trying that with the engine in place, although I think Dan (Florida) actually did it. My priority would have been to check the condition of the sump contents, on my "new" engine the pickup filter screen was 2/3 covered in old gasket material and other gunk. It still had good oil pressure, but needless to say I cleaned it well. I think yours may be really clogged with old gunk. Another idiot mode question: are you sure the gauge is working? Have you tried connecting another gauge? -- Joachim |

|||||||||

|

dmatth Member

|

Thanks for the suggestions! Greg, I did clean out the spring/plunger in the Pump Housing. Is there another something in the Aux Housing or are we talking about the same thing? Joachim, Thanks for the description. I guess the next step will be to remove the Aux Housing and see if i can draw oil up the pipe. Any idea how much/little effort should typically bring results? As for the gauge, that was on my agenda for today thought I might send 25lbs of air pressure up the tube and see if the gauge needle moves. Not feeling the the gauge is the culprit though since my test yesterday of removing oil cooler adapter seemed to leave the oil filter dry. Another thing I thought of trying is to drive the pump with a power tool to see if I can get a response. Doug |

|||||||||

|

subwoofer Member

|

I would hold back on removing the aux housing, I'm not quite sure taking it off would prove. Clean the relief valve again, making sure everything is squeaky clean. If you already have the cam belt off, try driving the aux shaft with some power tool to see if any pressure build. If you have had the distributor out, was the O-ring in good condition? The pump will not prime if the distributor is removed. If you spin the aux shaft with a drill, try taking the oil filter and oil cooler sandwich off to see if it pumps oil at all. No back pressure should make the oil flow. If there still is no sign of oil pressure, I'd drop the sump next. -- Joachim |

|||||||||

|

dmatth Member

|

I like the idea of not removing the aux housing (less work=more better), but I'm wondering if a clogged bleed hole could be a factor. Maybe with a mirror I'll be able to find the bleed hole with just the pump housing taken off. I'll be tinkering tonight, hopefully with some results. Doug |

|||||||||

|

SpeedyMitch Member

|

dmatth wrote: I'm wondering if a clogged bleed hole could be a factor Hay Doug, When I purchased my early JH last year it had never had the FSB applied to drill the air bleed hole in the Aux Housing. Without the air bleed hole it would take 20-30 seconds to build oil pressure. After drilling the bleed hole it now builds pressure in less than 5 seconds. If your JH is taking longer than 30 seconds to build oil pressure I doubt it is a plugged air bleed hole. Just my 2-cents (and worth every penny). Speedy Mitch |

|||||||||

|

terryhowarth Member

|

Hi all, I should have updated my problem months ago with the low oil pressure. As it turned out the PO had NEVER installed an olive into the pipe pickup at the block, all he did was ram some 1/2" plastic pipe down the oil pickup pipe and seal it with a piece of garden water hose & nut over that and sealing goop of some description. Then to top it off, a length of coiled metal spring about 12" long was shoved down that to stop the plastic pipe from being deformed by the engine oil heat. I removed the lot, fitted a new olive and nut and hey presto NO more oil pressure problems. might be worth checking it out as I'm sure there is more than 1 moron in the world. |

|||||||||

|

dmatth Member

|

SpeedyMitch wrote:

Good point. We've gone from good pressure (15-20 warm idle 45-50 running), to zero. So doubtful it's the bleed hole, I'll check it while I'm in there anyway. |

|||||||||

|

Greg Fletcher Administrator

|

The bleed hole may not be a big deal. It's great to put it in if that is not present when you are doing a rebuild, but my early Jensen Healeys never had it and they have always had excellent/instant oil pressure at startup. New oil pump rotors and engine bearings to spec will make a hugh difference compared to a high mileage engine. |

|||||||||

|

dmatth Member

|

So last night I tested the gauge, (it's working), pulled the oil pump housing, (the bypass plunger and spring are free and moving, I'll grease em up anyway). This weekend I'll put the pump housing and dist back on and give it a spin test with power tool. Not feeling very optimistic. After that I guess the next step is to pull the Aux Housing and see if I can draw up any oil manually (I'm thinking high tech – tubing, duct tape and shop vac). If not, then there must be something wrong/clogged at the pickup pipe. Then it's time for that garden hose clamp, tubing and a long spring q:) This is driving me bonkers. There aren't that many parts to the system. A pool of oil, a pump and some passages. Is it possible for a blocked passage to stop the pump from working? Oh BTW, when I put stuff back together I've been making paper gaskets and using a bit of gasket sealer instead of using Permatex silicon. Greg got me worried about goop squishing out to the inside and fouling stuff up. Doug Last edited on 06-23-2011 11:02 pm by dmatth |

|||||||||

|

subwoofer Member

|

The only place blockage before the rotor is likely is the pickup filter screen. The pickup line is such a massive diameter for anything to clog. My money is on the filter screen. -- Joachim |

|||||||||

|

dmatth Member

|

OK, so its got to be the oil pump. today we lubed up the bypass plunger with molly/graphite grease, and put the pump housing back on. I had a right-angle drive for a power drill and put an allen driver in the chuck and used that to the drive the pump at 1200 rpm with the oil filter off, (figuring that the oil pump sprocket is twice the size of the crank sprocket that would be equivalent to 2400 engine RPM). Not a trickle of oil pumped out. We removed the Aux housing and using the shop vac, duct tape and plastic tubing, we easily were able to draw oil up the pickup pipe. (at least I don't have to pull the engine again.) So what can go wrong in such a simple mechanism as an oil pump? All I can think of now is if the inner rotor is somehow no longer being driven by the shaft. Even worn rotors might drop your pressure some but we went from good pressure too zero. Doug |

|||||||||

|

subwoofer Member

|

Are you positive the distributor is mounted correctly and the O-ring intact? If there is an air leak there, the oil pump may not prime. Others have tried getting oil pressure with the distributor removed and failed. Edit: Idiot question mode again: You are sure you are spinning the pump the right way? -- Joachim Last edited on 06-27-2011 03:56 pm by subwoofer |

|||||||||

|

pbahr Member

|

Joachim beat me to the question about an air leak......... YELODOG |

|||||||||

|

dmatth Member

|

Well.... Yes, I'm positive we were spinning the pump the correct way, and yes the "O" ring on the dist is intact but no way of knowing if it is sealing other than the evidence that car does not seem to have been leaking oil at the dist mount, but then I guess once it looses its seal there would be no oil pressure nor oil to leak. (?) There is a very small hole at the back of the housing behind the inner rotor and drilled parallel to the drive shaft that I presume is the bleed hole from earlier discussions, it is blocked but appears to have been blocked for some time (really solidly blocked), and another larger hole (maybe .080 - .125 dia) angled up and looks to terminate at the gasket. Edit: We did have the dist mounted but without the cap in place. Looking at the rotors... If I saw these at a junk yard I'd buy them. No discernible signs of excess wear (car has 104k mi). The housing where the outer rotor spins shows some sign of scuffing but so little that there is no ridging between where the rotor spins and where it doesn't. The rotor fits with maybe (haven't measured yet) .010 clearance to the outside wall. Any ideas on how to bench test the pump?? Would I be able to spin it and just feel if it was drawing a vacuum? Last edited on 06-27-2011 08:09 pm by dmatth |

|||||||||

|

dmatth Member

|

New update: Talked with Delta Mortorsports today to order gaskets to put this thing back together and here's something that might be an issue: The gasket for the Pump housing is a "Precision" part at about .004" thickness. So my homemade paper gaskets may be the most recent problem. This still doesn't explain the sudden loss of pressure but hopefully with the right gaskets I can get this thing back on the road. The pessimist in me still wants to bench test before installing though. Don't want to mess up a $7 Aux Housing gasket until I am confident it's going to work. Thanks all, I'll let you know how it works. Doug Last edited on 06-28-2011 07:11 pm by dmatth |

|||||||||

|

subwoofer Member

|

I am at a loss here. There really are only two possible reasons, either it is drawing air somewhere, or something is clogged solid. For bench testing, you could possibly turn the aux housing over and pour oil into the oil intake while spinning the pump just to see that oil makes it to the other side, but I'm not sure if that will prove anything. -- Joachim |

|||||||||

|

dmatth Member

|

Here's the final chapter: Put everything together with the proper gaskets and Eureka, Oil pressure, Lots of it. Fired up with a cold start pressure at about 55lbs. So it seems obvious that the gasketing after my initial cleaning was the problem. However the mystery remains as to what caused the initial loss of pressure. My best guess would be the Oil Pump Housing gasket (the .004" mylar one) or the Dist seal, both of which were replaced. (The housing gasket came off in pieces) On another note, yes you can bench test an Oil Pump. I set the whole assembly on a workmate bench, used a piece of thick wall 3/4" OD plastic tubing, wrapped some electrical tape around one end so it fit snug in the oil pick up and the other end in a container of oil, taped off the upper hole to force the oil toward the filter passages, and use my DeWalt cordless with a 6mm alan driver in the chuck to drive the pump. On the first attempt the tubing was too long (in the real world the pump only draws up about 8-10"). With a shorter tube I was able to make a huge mess on the lower shelf of the workmate. Thanks everyone for your input! Doug Attachment: IMG_1374.JPG (Downloaded 81 times) |

|||||||||

|

subwoofer Member

|

Good to hear that everything worked out in the end! -- Joachim |

|||||||||

|

Spaceman Member

|

my first post to the forum since joining, my problem is too high of oil pressure, possibly caused by a stuck relief valve. Does anyone have an explanation of how the valve works? I have a spare, but dont' know if the guts are any good. Also, I have successfully repaired a busted oil gauge and am very proud of myself, if anyone would like to see the process, I can post some pics. |

|||||||||

|

Screenplay Member

|

Last edited on 06-13-2017 07:37 pm by Screenplay |

|||||||||

|

redracer Member

|

yes; I can help(as I'm sure many others can as well). Please try to explain where/what/how the "rebuild" is going. bruce madden |

|||||||||

|

Esprit2 Member

|

See the attached JPEG clipping from the JH Parts Manual. On the back end of the oil pump housing, next to the bore where the distributor installs, you'll see a second bore with a pressed-in steel plug with an O-ring seal (item 14). Under that plug there is a sleeve/ cylinder with ports cut in it's sides (item 17), a piston in the sleeve (item 16), and a coil spring (item 15) pressing the piston down to the bottom/ far end of the bore. The bore is a through hole, and breaks into the oil pump's 'working' area, on the high pressure side of the rotor and annulus (ring). As the pump builds oil pressure, the pressure pushes the spring-loaded piston up the bore, compressing the spring. Eventually the piston moves far enough up the bore to uncover the ports in the sleeve/ cylinder wall, and oil vents out of the port. The ports dump oil into an angled drilled passage that goes back to the inlet/ low pressure side of the oil pump's rotor & annulus. The port position (how far up the cylinder bore it's placed) and the strength of the coil spring determine the pressure at which the relief valve vents. That's designed and built in, and is not intended to be adjustable. However, some racers in search of a little more pressure have been known to shim the coil spring with a washer or two between the spring and the pressed-in plug/ cap. Or, old springs can fatigue and weaken over the years, allowing the piston to move too easily and vent oil at too low of a pressure. I do not know the correct spring rate, and to the best of my knowledge, replacement parts are no longer available. If any new springs do exist, they will be from JH specialists, since Lotus never did sell them, and Jensen is long out of business. Instead, Lotus preferred that you buy a replacement oil pump that is correctly calibrated. The piston can stick in the bore for a number of reasons, including galling, sludge gumming up the works, and corrosion. If the piston sticks at the bottom of the bore, no oil pressure will ever be vented, and peak pressure can become quite high... in excess of 60 psi. If the piston sticks at the top of the bore, with the ports uncovered, then oil pressure will vent and be low to non-existent. The piston can stick anywhere along the bore, so the failure symptoms can be either very high or very low oil pressure. Or it can be erratic. *~*~* Oil pressure that builds very slowly on cold start-up is probably caused by something other than a faulty pressure relief valve. Never say never, but don't focus exclusively on the relief valve and over-look other possibilities. Other possibilities include a plugged breather hole in the auxiliary housing, just inside where the oil pump bolts on, a plugged oil pick-up screen, or an air leak anywhere on the suction side of the oil pump or the passages that feed oil to it. Good luck, Tim Engel Attachment: 9XX Lubrication - Oil Pump, Pressure Relief Valve - Exploded Parts - All 9XX.jpg (Downloaded 146 times) Last edited on 10-25-2018 12:41 am by Esprit2 |

|||||||||

|

Esprit2 Member

|

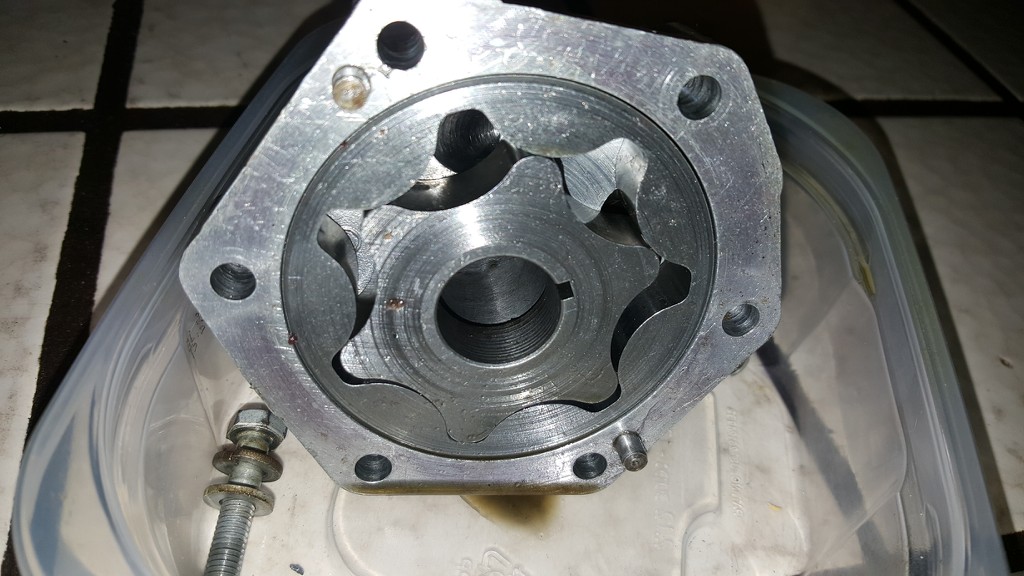

Here are the pressure relief valve's internal parts laid out. It's not my photo, but I don't recall where I got it. These parts are typical of the Lotus and Mk II JH oil pumps, while the Mk I JH has a different piston config. Look past the details, and both versions work basically the same way. Regards, Tim Engel Attachment: 9XX Lubrication - Oil Pressure Regulator 06.jpg (Downloaded 146 times) Last edited on 06-15-2017 07:58 pm by Esprit2 |

|||||||||

|

Esprit2 Member

|

And another view, with the parts nested together. Attachment: 9XX Lubrication - Oil Pressure Regulator 08.jpg (Downloaded 149 times) |

|||||||||

|

Esprit2 Member

|

For 'slow' oil pressure build-up on cold start, make certain this air bleed hole is clean, and not plugged with sludge. Attachment: 9XX Lubrication - Oil Pump, Aux Housing Air Bleed Location - illus, cropped with notes.jpg (Downloaded 150 times) |

|||||||||

|

Harkes Member

|

I'm having issues getting oil pressure after long oil change and the car having sit still for a number of years. It is a relatively fresh engine after rebuilt some years ago. I'm suspecting an air leak of sorts with the oil pressure regulator as likely suspect. I had the oil pump housing off (aux housing still on the car), but don't know how to get the oil pressure regulator out. Or at least there is no pin that i can drive out. (my car is a Mk II) I looked at the oil pressure regulator Tim sent, and it looks like i have similar one. Can anyone tell me how to get this one out of its housing? Or is it non-re-serviceable? Also if I look inside the oil pump housing from aux housing side, then I see that the oil pressure regulator is pretty far in there. Is that the way it is supposed to be? With a screw driver I can press it in still though very smoothly. Could it also be i miss a part of oil pressure regulator? (the most left part in Tim Engel's picture) Appreciate your help guys. Last edited on 10-19-2020 11:25 am by Harkes |

|||||||||

|

redracer Member

|

The small split pin(about 1/8" diameter) is on the back and gets pushed into the space for the distributor shaft. I just noticed after looking at the picture for the pressure relief, that the sliding steel piece(the 2nd item from the left inn the pic Tim obtained) is facing the wrong direction. The hollow portion faces front with the bulge on the back to capture the spring. It would have been better to have removed the timing belt from the sprocket and use a drill to turn the pump to see if you got pressure(this is the way I pre-pressurize all my engine rebuilds). big question: did you get good pressure before? |

|||||||||

|

Harkes Member

|

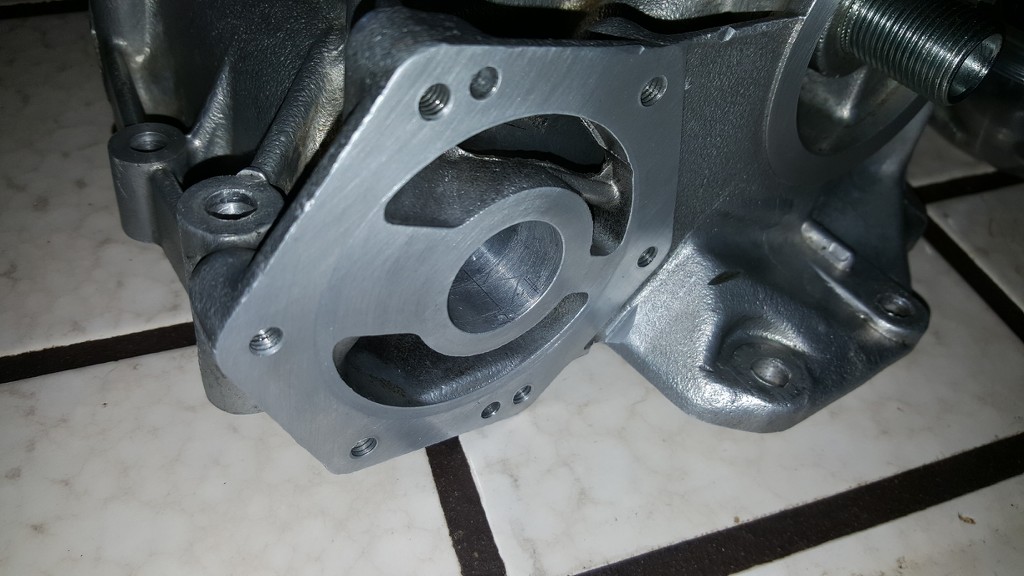

I have added a picture of the oil pump housing seen from the aux housing side. This is not mine, but mine is exactly the same and my oil pressure regulator looks the same and sits as deep as this one. Attachment: IMGP1140.JPG (Downloaded 95 times) |

|||||||||

|

Harkes Member

|

Thanks for you quick response Bruce. Much appreciated. I did have good oil pressure before. I have added another picture that shows a view of the other side of the oil pump housing. (also not mine, but exactly the same). There is no pin that can be driven out from distributor side, which are normally found. I think mine is from a Lotus Excel or so. I will definitely try and remove the belt and spin the aux pulley. Somehow during the long oil change, i must have lost prime. Should I pack the oil pump rotors with vaseline (petroleum jelly) and then spin the aux pulley with a drill? I presume I should turn it unit oil comes out at the cams correct? Attachment: P1011314.JPG (Downloaded 96 times) |

|||||||||

|

redracer Member

|

didn't realize you had taken the oil pump housing off the auxiliary housing(the split pin is in the back side of your pic). Unfortunately, there is a special plastic thickness gasket that goes between the auxiliary housing and the pump housing in 5 different thicknesses.(0.005"-0.0015") . Most of the time the 0.005" gasket has been used, and a few times I have needed the 0.004" size, but you will need to measure the for-aft movement now. I use 0.0005-0.001" for the gap; any more gap leads to too much air |

|||||||||

|

redracer Member

|

Just got your reply while I was typing mine: do NOT use vaseline. maybe a very thin CLEAN grease such as MoS2/etc., but if there is no pin, I don't know what to say--maybe Tim can step in here as he is the LOTUS expert |

|||||||||

|

Harkes Member

|

Thanks Bruce, I will use MoS2 and spin the aux pulley until oil reaches the cams and check oil pressure on the gauge in the car. I will also check pump clearance. The gasket that was on it was a clear white plastic one. |

|||||||||

|

discogodfather Member

|

I recently rebuilt mine and found this video. This guy has the early style oil pressure relief setup with fewer parts, but it's all relatively the same. I used a little aviation sealant on the o-ring on the cap that holds the oil pressure relief setup. That seems to seep a little over time, and it has worked as it's bone dry after a few hundred miles. As with everything else 907 the tolerance on that small o-ring is very tight, I tried using a replacement out of a buna-n kit I had and it kept splitting the O-ring. Ended up ordering the OEM part. Lots of assembly lube on re-install is always a good idea. Helps to prime it a bit too by pouring some oil in the filter. Another good idea is to replace the round keeper clip - that silly little clip actually holds the entire oil system together. Mine was bowed badly and the distributor kept popping off of it as the entire shaft slid forward. https://www.youtube.com/watch?v=mhKCQqUQoLs |

|||||||||

|

discogodfather Member

|

I also tried to clean the mating surfaces real well and was careful to insert the rotor and outer gear back in the same way they came apart, matching the wear patterns. It seems bad if you were to swap that around. I think some pump rotors and outer gears have a mark on them to signify this relationship, but for some reason mine did not have the little star like mark. And that plastic spacer is very important, get a new one. If it binds hard or drags a bit using two of the plastic gaskets is recommended. When assembled it should spin very freely.     Last edited on 10-21-2020 02:17 am by discogodfather |

|||||||||

|

Harkes Member

|

Very helpful to see pictures. I can see that your oil pressure relief valve sits as deep in the housing as mine, which makes me feel relieved. I have measured the end rotor clearance, new gasket and all is back together again. Waiting for my battery driven wrench which will allow me to spin the aux pulley without having to pull the radiator out. Already have the belt off. Hopefully it will prime and I get to see good pressure readings on the gauge. |

|||||||||

|

Harkes Member

|

Finally had the battery driven wrench in. Took the drive belt off, all spark plugs out, distributor fitted and spun the aux pulley. I noticed it became harder for the battery driven wrench to turn it around once I saw oil coming up at the cams. I gave a bit more and decided it should be sufficient. Then fitted the drive belt and with all 4 spark plugs out, I cranked the engine several times. I was still getting oil to the cams, but zero reading on the oil pressure gauge inside the cockpit. Pulled the oil pressure line at the engine and saw no oil whatsoever. I realise there is usually air and oil in the oil pressure line. This could mean little or no oil towards the crank or a faulty oil pressure gauge? I'm at a loss right now. Any one any ideas what to do next? Should I spin it some more with the drive belt off and also with the oil pressure line off at the block until oil comes out there? Appreciate your help guys. Last edited on 11-01-2020 02:52 pm by Harkes |

|||||||||

|

discogodfather Member

|

Are you sure you put the oil pressure relief piston in the right way? The cupped end points to the front of the car. It's easy to switch that and be very confused, with the flat end obstructing the passage. In my experience it takes a long time for the pump to get going and generate pressure, and even then it kind of farts out some of the air and the pressure can go up and down a bit in the beginning. I don't have to worry because I have an accusump on it, so I can use that pressure to get the engine through the first few seconds. I also run a mechanical oil pressure gauge, so no help there in regards to your issue. Did you fill up the oil filter with some oil? |

|||||||||

|

Harkes Member

|

thank you very much for your response. When I took the oil pump housing off, there was no way for me to disassemble the oil pressure relief valve. I seem to have a different model (probably Lotus Excel version) which doesn't have a pin to drive out that locks the oil pressure relief valve in place. That said, the oil pump is definitely primed. If I turn the aux pulley by hand i can tell there is quite some resistance which wasn't there when the pump was not primed. I'm getting oil all the way up in the cam housing and quite a bit too and knowing I have an oil restrictor to the head, this is good news. It is just that i'm having doubts as to whether or not the cranks is getting oil as I have no oil pressure reading on my gauge. There is the small chance that my oil pressure line is clogged or the oil pressure gauge is not working, or there is still air trapped as you say. I have decided to rule out the obvious, so I will first check the oil pressure line to see if it is clogged and blow it out using compressed air, I will check the oil pressure gauge with my air compressor gun to see if it gives any reading. If the gauge works ok, then i will bleed the oil pressure line by spinning the aux pulley (drive belt off) again with the oil pressure line to the oil pressure gauge off. As soon as oil comes "gushing" out on the far end of the oil pressure line, then I should get pressure reading on the gauge so then I'll connect the oil pressure line to the gauge again. Hope this works, otherwise I need to start over and backtrack where things might go wrong. I will send an update as soon as i can. |

|||||||||

|

redracer Member

|

You may want to rig up a colorless line from the block where the plastic tube come out: the threaded side into the engine block plate is 1/8" NPT(27 threads/inch; however, the other side going into the plastic line is 1/8" BSP--28 threads/inch) . Put the colorless tube onto a barbed fitting and run that into some kind of catch tank so you don't make a mess. Also, I would suggest spinning the shaft with a 17mm bolt instead of the 6mm allen hole, as the hole WILL get wallowed out. keep us posted, bruce |

|||||||||

|

Harkes Member

|

Thanks Bruce, great idea to use a transparant/colorless line and a catch tank at the other end. we'll keep you posted. |

|||||||||

|

Harkes Member

|

Good news, we have good oil pressure readings! Took the drive belt of again this weekend, took the oil pressure line off and cleaned it. Checked the oil pressure gauge with pressed air to see if it still worked and it did. So with the oil pressure line off I spun the aux pulley until I saw oil gushing out the other end (and into a water bottle which I taped off to prevent a mess). I then connected the oil pressure line again, spun it some more and instantly I had very good oil pressure reading on the gauge. I had my daughter checking the gauge in the car and filming it. It is a bit of a flimsy video, but I'm very happy all is good now. https://www.youtube.com/watch?v=4AMr4na8YNw Installed the JAE blue racing belt (half moon type) again and tensioned it at 100 Hz using the Gates Carbon Drive app. Now need to check static timing, recharge battery and then it is time to fire this baby up. Thanks for your help all Last edited on 11-09-2020 09:14 am by Harkes |

|||||||||

|

Harkes Member

|

With the fuel pump happily ticking and carbs working properly again, new oil, oil filter and coolant, I'm getting close to starting the engine. (a month or two go I had to completely clean the carbs inside out as there was no fuel coming out at all. This was a fun and rewarding project by the way. Not only do they function properly again, but they look like new as well.) Just a quick picture of what the engine bay looks like now. Attachment: IMG_6163.jpeg (Downloaded 61 times) |

|||||||||

|

redracer Member

|

we're all happy to hear you got that sorted out--so exactly, what was the problem? Noticed the pressure only went to just above 50psi(the original relief was set at 55psi). With COLD oil, the initial pressure should be much higher and as it warms up, it will drop down. Hopefully, your drill has a 3000rpm(or higher) setting on it(if you used a cordless one, then the low psi is understandable) |

|||||||||

|

Harkes Member

|

Hi Bruce, thanks and well spotted. My drill is a cordless one which goes up to about 250 rpm and I didn't run it at full speed either as I was still using the allen bit and I didn't want to ruin the aux pulley allen bolt. I think to be honest I did not spin the aux pulley long enough the first time around. I stopped when I saw lots of oil coming up at the cams and thought that was good enough. Second time around I waited until oil came out the other end of the oil pressure line which took just a little longer... I don't think the oil pressure line was clogged or anything as almost nothing came out when I blew it out with pressed air. |

|||||||||

|

redracer Member

|

removing the allen bolt may be a little daunting at first, but if you use a set of vise grips on the large washer(yes, it WILL leave some indentation marks) and rotate that along with the allen screw(put a rod through one of the sprocket holes to prevent it form rotating), it should come apart so you could use a hex bolt for the pump priming. Recommend antisieze when reinstalling |

|||||||||

|

Harkes Member

|

I will certainly do that a next time. I don't want to wear out the allen bolt on the aux pulley in the near future. For now my cordless tool was really handy and got the job done. My oil pump is primed and I feel confident that it builds good oil pressure given the limited rpm. My guess is that I ran the pulley around 150 to 200 rpm. If I would run it all full speed (250 rpm) with a hex bolt, I don't think it would give a much higher oil pressure reading. For that I would need a tool that would allow 3000 rpm or more as you said. I will run final checks (as I have done quite a few updates this year on the car) and try and start her up....cross fingers. Last edited on 11-09-2020 03:50 pm by Harkes |

|||||||||

|

discogodfather Member

|

Nice engine compartment! |

|||||||||