| ||||

| ||||

| Moderated by: Greg Fletcher | Page:   1 2 3 4 1 2 3 4   |

|

|||||||||||||

| Oil pump rebuild | Rating:

|

| Author | Post |

|---|

| Posted: 06-13-2017 06:41 pm |

|

41st Post |

|

Spaceman Member

|

my first post to the forum since joining, my problem is too high of oil pressure, possibly caused by a stuck relief valve. Does anyone have an explanation of how the valve works? I have a spare, but dont' know if the guts are any good. Also, I have successfully repaired a busted oil gauge and am very proud of myself, if anyone would like to see the process, I can post some pics.

|

||||||||||||||

| |||||||||||||||

| Posted: 06-13-2017 06:58 pm |

|

42nd Post |

|

Screenplay Member

|

Last edited on 06-13-2017 07:37 pm by Screenplay |

|||||||||||||

| ||||||||||||||

| Posted: 06-14-2017 12:32 am |

|

43rd Post |

|

redracer Member

|

yes; I can help(as I'm sure many others can as well). Please try to explain where/what/how the "rebuild" is going. bruce madden

|

||||||||||||||

| |||||||||||||||

| Posted: 06-14-2017 11:22 pm |

|

44th Post |

|

Esprit2 Member

|

See the attached JPEG clipping from the JH Parts Manual. On the back end of the oil pump housing, next to the bore where the distributor installs, you'll see a second bore with a pressed-in steel plug with an O-ring seal (item 14). Under that plug there is a sleeve/ cylinder with ports cut in it's sides (item 17), a piston in the sleeve (item 16), and a coil spring (item 15) pressing the piston down to the bottom/ far end of the bore. The bore is a through hole, and breaks into the oil pump's 'working' area, on the high pressure side of the rotor and annulus (ring). As the pump builds oil pressure, the pressure pushes the spring-loaded piston up the bore, compressing the spring. Eventually the piston moves far enough up the bore to uncover the ports in the sleeve/ cylinder wall, and oil vents out of the port. The ports dump oil into an angled drilled passage that goes back to the inlet/ low pressure side of the oil pump's rotor & annulus. The port position (how far up the cylinder bore it's placed) and the strength of the coil spring determine the pressure at which the relief valve vents. That's designed and built in, and is not intended to be adjustable. However, some racers in search of a little more pressure have been known to shim the coil spring with a washer or two between the spring and the pressed-in plug/ cap. Or, old springs can fatigue and weaken over the years, allowing the piston to move too easily and vent oil at too low of a pressure. I do not know the correct spring rate, and to the best of my knowledge, replacement parts are no longer available. If any new springs do exist, they will be from JH specialists, since Lotus never did sell them, and Jensen is long out of business. Instead, Lotus preferred that you buy a replacement oil pump that is correctly calibrated. The piston can stick in the bore for a number of reasons, including galling, sludge gumming up the works, and corrosion. If the piston sticks at the bottom of the bore, no oil pressure will ever be vented, and peak pressure can become quite high... in excess of 60 psi. If the piston sticks at the top of the bore, with the ports uncovered, then oil pressure will vent and be low to non-existent. The piston can stick anywhere along the bore, so the failure symptoms can be either very high or very low oil pressure. Or it can be erratic. *~*~* Oil pressure that builds very slowly on cold start-up is probably caused by something other than a faulty pressure relief valve. Never say never, but don't focus exclusively on the relief valve and over-look other possibilities. Other possibilities include a plugged breather hole in the auxiliary housing, just inside where the oil pump bolts on, a plugged oil pick-up screen, or an air leak anywhere on the suction side of the oil pump or the passages that feed oil to it. Good luck, Tim Engel Attachment: 9XX Lubrication - Oil Pump, Pressure Relief Valve - Exploded Parts - All 9XX.jpg (Downloaded 146 times) Last edited on 10-25-2018 12:41 am by Esprit2 |

|||||||||||||

| ||||||||||||||

| Posted: 06-14-2017 11:28 pm |

|

45th Post |

|

Esprit2 Member

|

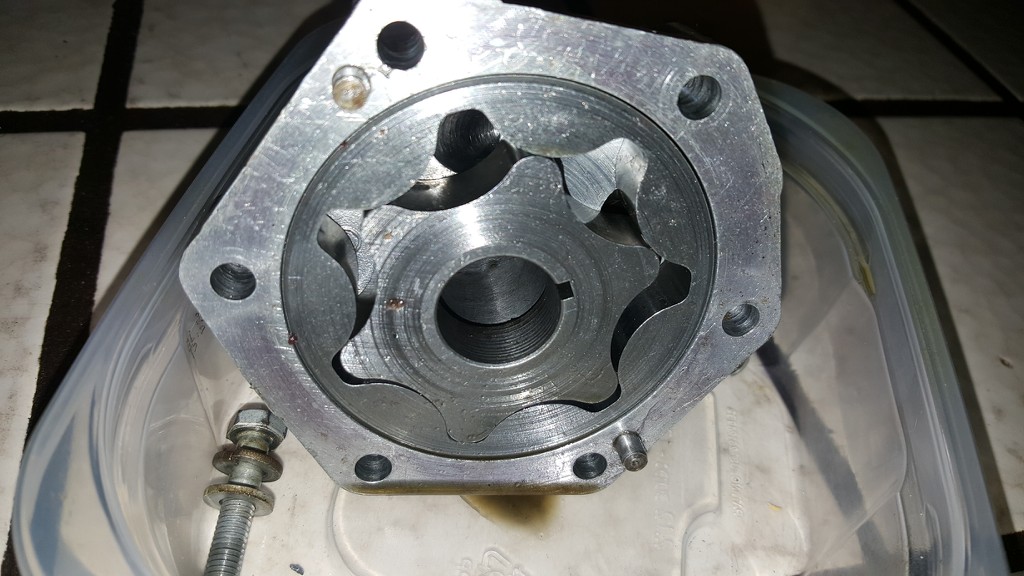

Here are the pressure relief valve's internal parts laid out. It's not my photo, but I don't recall where I got it. These parts are typical of the Lotus and Mk II JH oil pumps, while the Mk I JH has a different piston config. Look past the details, and both versions work basically the same way. Regards, Tim Engel Attachment: 9XX Lubrication - Oil Pressure Regulator 06.jpg (Downloaded 146 times) Last edited on 06-15-2017 07:58 pm by Esprit2 |

||||||||||||||

| |||||||||||||||

| Posted: 06-14-2017 11:34 pm |

|

46th Post |

|

Esprit2 Member

|

And another view, with the parts nested together. Attachment: 9XX Lubrication - Oil Pressure Regulator 08.jpg (Downloaded 149 times)

|

|||||||||||||

| ||||||||||||||

| Posted: 06-14-2017 11:38 pm |

|

47th Post |

|

Esprit2 Member

|

For 'slow' oil pressure build-up on cold start, make certain this air bleed hole is clean, and not plugged with sludge. Attachment: 9XX Lubrication - Oil Pump, Aux Housing Air Bleed Location - illus, cropped with notes.jpg (Downloaded 150 times)

|

||||||||||||||

| |||||||||||||||

| Posted: 10-19-2020 11:23 am |

|

48th Post |

|

Harkes Member

|

I'm having issues getting oil pressure after long oil change and the car having sit still for a number of years. It is a relatively fresh engine after rebuilt some years ago. I'm suspecting an air leak of sorts with the oil pressure regulator as likely suspect. I had the oil pump housing off (aux housing still on the car), but don't know how to get the oil pressure regulator out. Or at least there is no pin that i can drive out. (my car is a Mk II) I looked at the oil pressure regulator Tim sent, and it looks like i have similar one. Can anyone tell me how to get this one out of its housing? Or is it non-re-serviceable? Also if I look inside the oil pump housing from aux housing side, then I see that the oil pressure regulator is pretty far in there. Is that the way it is supposed to be? With a screw driver I can press it in still though very smoothly. Could it also be i miss a part of oil pressure regulator? (the most left part in Tim Engel's picture) Appreciate your help guys. Last edited on 10-19-2020 11:25 am by Harkes |

|||||||||||||

| ||||||||||||||

| Posted: 10-19-2020 02:01 pm |

|

49th Post |

|

redracer Member

|

The small split pin(about 1/8" diameter) is on the back and gets pushed into the space for the distributor shaft. I just noticed after looking at the picture for the pressure relief, that the sliding steel piece(the 2nd item from the left inn the pic Tim obtained) is facing the wrong direction. The hollow portion faces front with the bulge on the back to capture the spring. It would have been better to have removed the timing belt from the sprocket and use a drill to turn the pump to see if you got pressure(this is the way I pre-pressurize all my engine rebuilds). big question: did you get good pressure before?

|

||||||||||||||

| |||||||||||||||

| Posted: 10-19-2020 02:07 pm |

|

50th Post |

|

Harkes Member

|

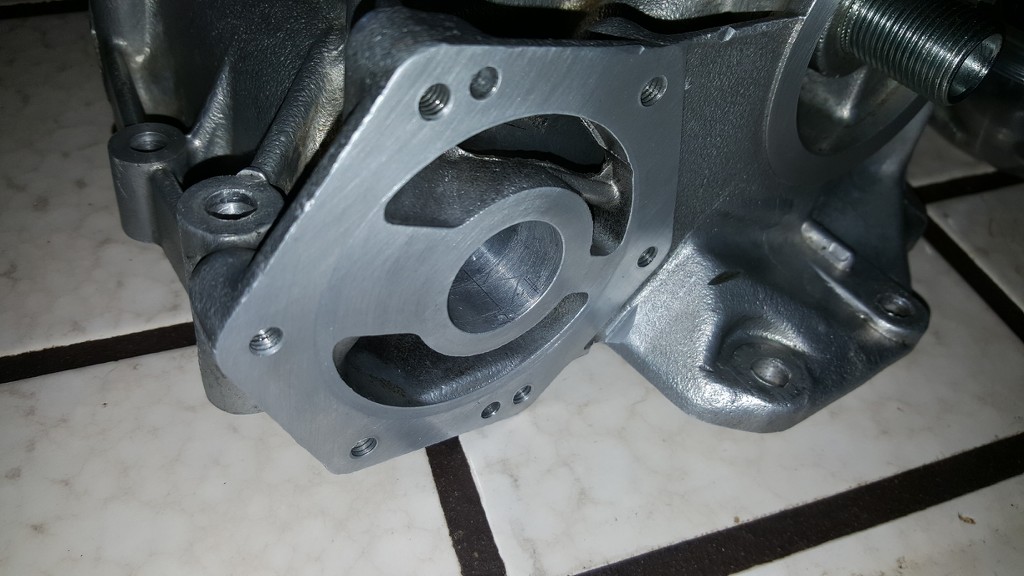

I have added a picture of the oil pump housing seen from the aux housing side. This is not mine, but mine is exactly the same and my oil pressure regulator looks the same and sits as deep as this one. Attachment: IMGP1140.JPG (Downloaded 95 times)

|

|||||||||||||

| ||||||||||||||

| Posted: 10-19-2020 02:20 pm |

|

51st Post |

|

Harkes Member

|

Thanks for you quick response Bruce. Much appreciated. I did have good oil pressure before. I have added another picture that shows a view of the other side of the oil pump housing. (also not mine, but exactly the same). There is no pin that can be driven out from distributor side, which are normally found. I think mine is from a Lotus Excel or so. I will definitely try and remove the belt and spin the aux pulley. Somehow during the long oil change, i must have lost prime. Should I pack the oil pump rotors with vaseline (petroleum jelly) and then spin the aux pulley with a drill? I presume I should turn it unit oil comes out at the cams correct? Attachment: P1011314.JPG (Downloaded 96 times)

|

||||||||||||||

| |||||||||||||||

| Posted: 10-19-2020 02:22 pm |

|

52nd Post |

|

redracer Member

|

didn't realize you had taken the oil pump housing off the auxiliary housing(the split pin is in the back side of your pic). Unfortunately, there is a special plastic thickness gasket that goes between the auxiliary housing and the pump housing in 5 different thicknesses.(0.005"-0.0015") . Most of the time the 0.005" gasket has been used, and a few times I have needed the 0.004" size, but you will need to measure the for-aft movement now. I use 0.0005-0.001" for the gap; any more gap leads to too much air

|

|||||||||||||

| ||||||||||||||

| Posted: 10-19-2020 02:26 pm |

|

53rd Post |

|

redracer Member

|

Just got your reply while I was typing mine: do NOT use vaseline. maybe a very thin CLEAN grease such as MoS2/etc., but if there is no pin, I don't know what to say--maybe Tim can step in here as he is the LOTUS expert

|

||||||||||||||

| |||||||||||||||

| Posted: 10-19-2020 03:53 pm |

|

54th Post |

|

Harkes Member

|

Thanks Bruce, I will use MoS2 and spin the aux pulley until oil reaches the cams and check oil pressure on the gauge in the car. I will also check pump clearance. The gasket that was on it was a clear white plastic one.

|

|||||||||||||

| ||||||||||||||

| Posted: 10-21-2020 02:11 am |

|

55th Post |

|

discogodfather Member

|

I recently rebuilt mine and found this video. This guy has the early style oil pressure relief setup with fewer parts, but it's all relatively the same. I used a little aviation sealant on the o-ring on the cap that holds the oil pressure relief setup. That seems to seep a little over time, and it has worked as it's bone dry after a few hundred miles. As with everything else 907 the tolerance on that small o-ring is very tight, I tried using a replacement out of a buna-n kit I had and it kept splitting the O-ring. Ended up ordering the OEM part. Lots of assembly lube on re-install is always a good idea. Helps to prime it a bit too by pouring some oil in the filter. Another good idea is to replace the round keeper clip - that silly little clip actually holds the entire oil system together. Mine was bowed badly and the distributor kept popping off of it as the entire shaft slid forward. https://www.youtube.com/watch?v=mhKCQqUQoLs

|

||||||||||||||

| |||||||||||||||

| Posted: 10-21-2020 02:16 am |

|

56th Post |

|

discogodfather Member

|

I also tried to clean the mating surfaces real well and was careful to insert the rotor and outer gear back in the same way they came apart, matching the wear patterns. It seems bad if you were to swap that around. I think some pump rotors and outer gears have a mark on them to signify this relationship, but for some reason mine did not have the little star like mark. And that plastic spacer is very important, get a new one. If it binds hard or drags a bit using two of the plastic gaskets is recommended. When assembled it should spin very freely.     Last edited on 10-21-2020 02:17 am by discogodfather |

|||||||||||||

| ||||||||||||||

| Posted: 10-22-2020 03:22 pm |

|

57th Post |

|

Harkes Member

|

Very helpful to see pictures. I can see that your oil pressure relief valve sits as deep in the housing as mine, which makes me feel relieved. I have measured the end rotor clearance, new gasket and all is back together again. Waiting for my battery driven wrench which will allow me to spin the aux pulley without having to pull the radiator out. Already have the belt off. Hopefully it will prime and I get to see good pressure readings on the gauge.

|

||||||||||||||

| |||||||||||||||

| Posted: 11-01-2020 02:50 pm |

|

58th Post |

|

Harkes Member

|

Finally had the battery driven wrench in. Took the drive belt off, all spark plugs out, distributor fitted and spun the aux pulley. I noticed it became harder for the battery driven wrench to turn it around once I saw oil coming up at the cams. I gave a bit more and decided it should be sufficient. Then fitted the drive belt and with all 4 spark plugs out, I cranked the engine several times. I was still getting oil to the cams, but zero reading on the oil pressure gauge inside the cockpit. Pulled the oil pressure line at the engine and saw no oil whatsoever. I realise there is usually air and oil in the oil pressure line. This could mean little or no oil towards the crank or a faulty oil pressure gauge? I'm at a loss right now. Any one any ideas what to do next? Should I spin it some more with the drive belt off and also with the oil pressure line off at the block until oil comes out there? Appreciate your help guys. Last edited on 11-01-2020 02:52 pm by Harkes |

|||||||||||||

| ||||||||||||||

| Posted: 11-02-2020 08:42 am |

|

59th Post |

|

discogodfather Member

|

Are you sure you put the oil pressure relief piston in the right way? The cupped end points to the front of the car. It's easy to switch that and be very confused, with the flat end obstructing the passage. In my experience it takes a long time for the pump to get going and generate pressure, and even then it kind of farts out some of the air and the pressure can go up and down a bit in the beginning. I don't have to worry because I have an accusump on it, so I can use that pressure to get the engine through the first few seconds. I also run a mechanical oil pressure gauge, so no help there in regards to your issue. Did you fill up the oil filter with some oil?

|

||||||||||||||

| |||||||||||||||

| Posted: 11-02-2020 10:29 am |

|

60th Post |

|

Harkes Member

|

thank you very much for your response. When I took the oil pump housing off, there was no way for me to disassemble the oil pressure relief valve. I seem to have a different model (probably Lotus Excel version) which doesn't have a pin to drive out that locks the oil pressure relief valve in place. That said, the oil pump is definitely primed. If I turn the aux pulley by hand i can tell there is quite some resistance which wasn't there when the pump was not primed. I'm getting oil all the way up in the cam housing and quite a bit too and knowing I have an oil restrictor to the head, this is good news. It is just that i'm having doubts as to whether or not the cranks is getting oil as I have no oil pressure reading on my gauge. There is the small chance that my oil pressure line is clogged or the oil pressure gauge is not working, or there is still air trapped as you say. I have decided to rule out the obvious, so I will first check the oil pressure line to see if it is clogged and blow it out using compressed air, I will check the oil pressure gauge with my air compressor gun to see if it gives any reading. If the gauge works ok, then i will bleed the oil pressure line by spinning the aux pulley (drive belt off) again with the oil pressure line to the oil pressure gauge off. As soon as oil comes "gushing" out on the far end of the oil pressure line, then I should get pressure reading on the gauge so then I'll connect the oil pressure line to the gauge again. Hope this works, otherwise I need to start over and backtrack where things might go wrong. I will send an update as soon as i can.

|

|||||||||||||

| ||||||||||||||

| Current time is 04:43 pm | Page:   1 2 3 4 1 2 3 4   |

| > Jensen Healey & Jensen GT Tech > Engine & Transmission > Oil pump rebuild | Top |