| PM | Quote | Reply | Full Topic |

| Joined: | 09-17-2007 |

| Location: | San Francisco, California USA |

| Posts: | 221 |

| Status: |

Offline

|

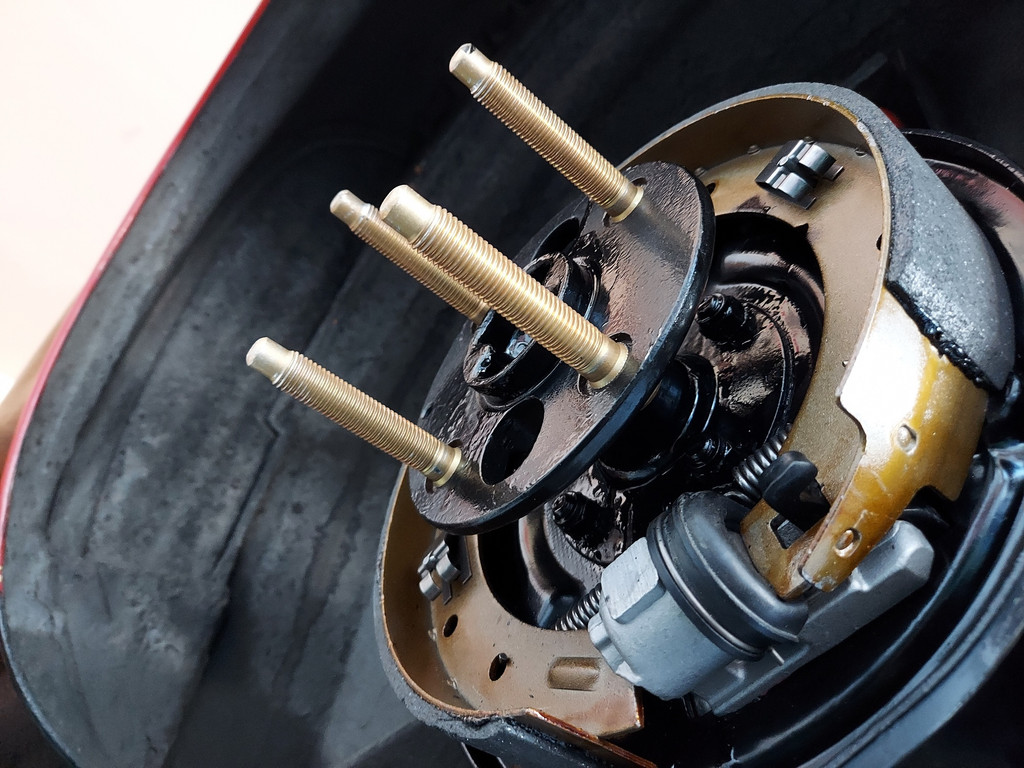

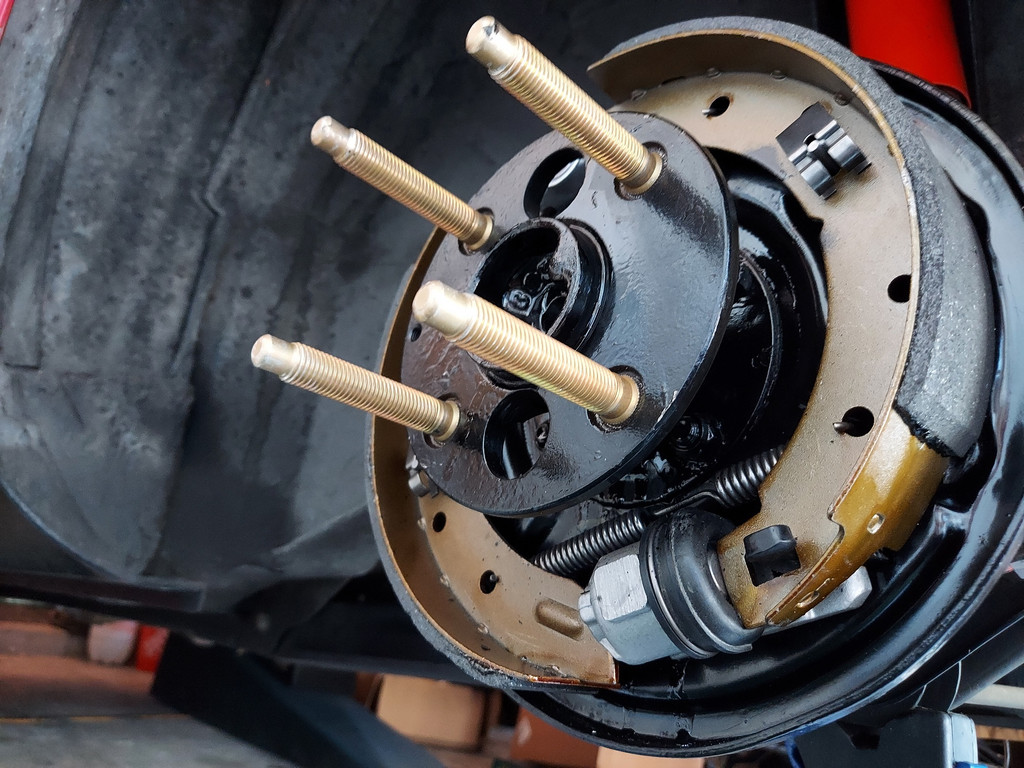

Another problem- the geometry of the threaded area isn't right. The stock studs end their threads before they contact the drum, so the studs basically don't support the drum using the threads only. The ARP studs (from the GM late model kit) don't do this- it's all threads.

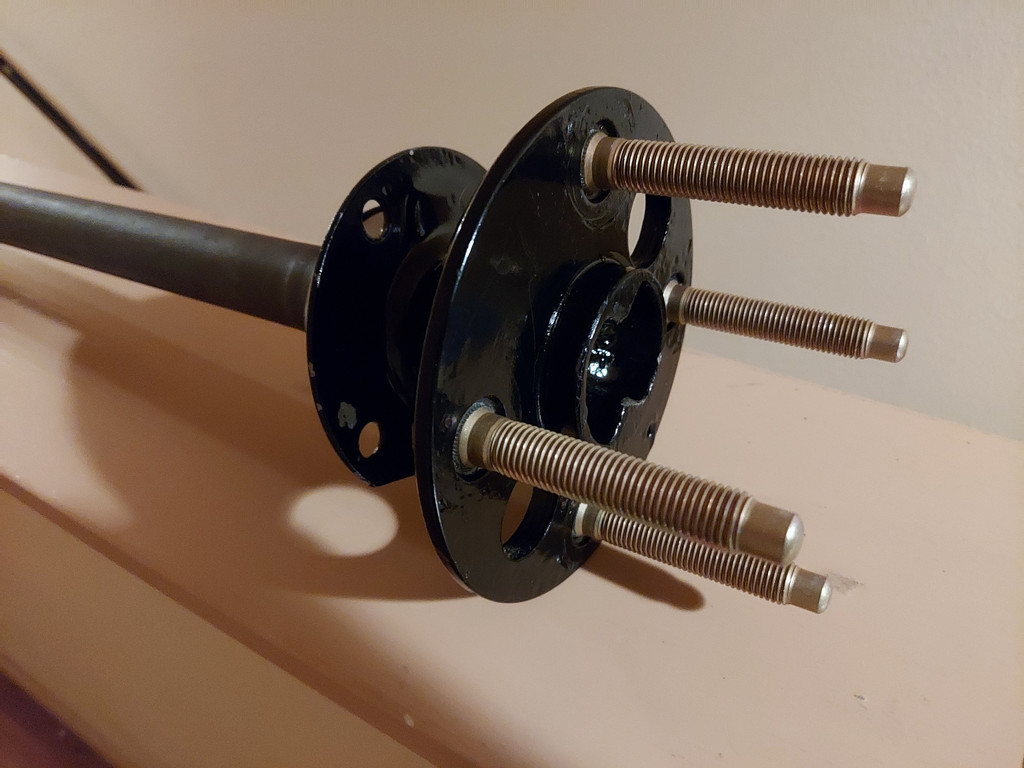

So back to the drawing board, this time really analyzed the geometry needed. Found an Evolution 8 ARP kit (Mitsubishi) and it was oversize on the "knurl".

Used a 14mm drill to make new holes, using a drill press, as noted in the ARP online how to. Pressed in the new studs one at a time and got a good 4 tons of pressure on each one, now very firmly seated and zero wobble.

Also drilled the drum holes out to accept 12mm, had to used a 12.5mm drill bit because at 12mm it was just too tight.

New studs are better than the old ones in that they have the "speed" smooth ends that look good and are very practical (saves the threads). I think ARP calls this a "speed stud", ala Nascar.

Now I have to do the fronts!