| PM | Quote | Reply | Full Topic |

| Joined: | 09-17-2007 |

| Location: | San Francisco, California USA |

| Posts: | 221 |

| Status: |

Offline

|

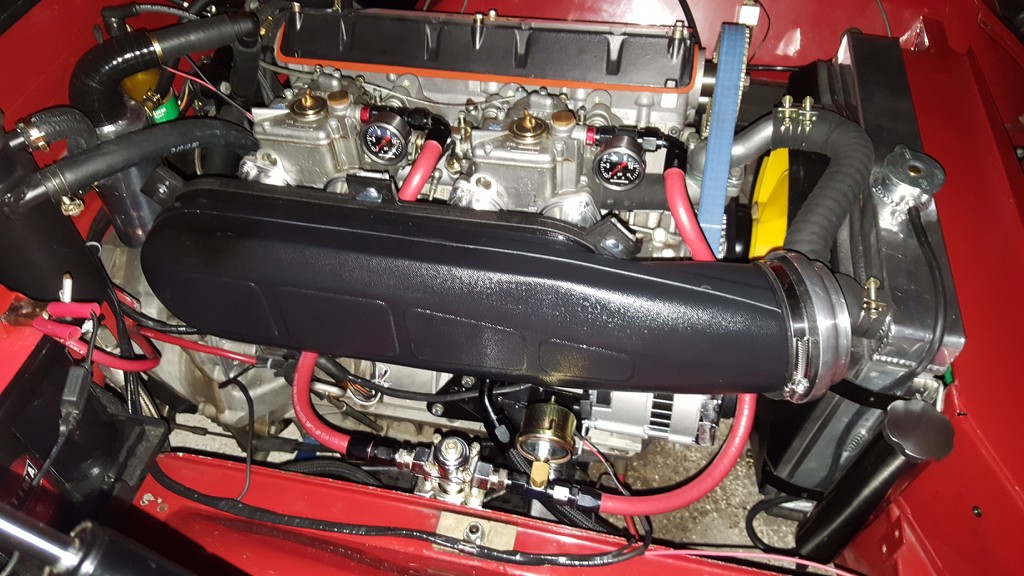

With this 104 cam and the headers and the Weber 45's, she always ran best with extremely long velocity stacks (air horns) at around 4". I loved the stacks, but hated any air cleaner option out there. I tried some foam socks and they were atrocious. The performance went down so significantly with these socks on it wasn't worth running the stacks. I tried some minimal flat screens, but lets be honest: these aren't air filters. I ended up loosing two on the freeway one day so they aren't really worth it either.

Factory air boxes were on the large side and could accommodate long stacks but they were hens teeth, and the ones I did find were falling apart. No problem, I can do some fiberglass work, but finding one even remotely worth of patching up was also nearly impossible. Factory air boxes also fed centrally, since the "muffler" style air canister sat on top of the passengers side wheel well. So it wasn't the best place to run a hose, since I wanted to put the hose 90 degrees downward from the front of the airbox into a 4" hose that would run into the area in front of the passengers wheel and out to below the bumper.

I started to look at universal airboxes. There is an outfit called EPI in Australia that made a large universal fiberglass box that would allow for long air horns, but it was rather large and hefty. I didn't like the look of a massive air box on these beautiful engines, I like to be able to see as much of the engine as possible. The EPI required a lot of custom work to cut out the back of the box to fit the weber intake pattern. Even then all dimensions seemed close- like in the mm's of clearance. On the back you have the oil canister, under you got the starter, and in front you got the alternator. Big chance you could no longer reach the dipstick!

So I needed something small enough to fit, and found the Pipercross 600 series. They are a UK company and the 600 is a universal box designed for tight installs. Used mostly in Lotus 7 style cars with twin cams, mazda miata engines, etc. It's got an aluminum back plate that can be ordered blank for custom fitment. I saw that they had a list of cutouts available, and then the Talbot Sunbeam Lotus cutout caught my eye. Ordered than one.

The Talbot Sunbeam Lotus used a 911 engine if I recall correctly, when twin Dells (maybe a 912??). I was counting on the spacing being the same as a 907. Turns out I think the 911 engine used a larger 48mm carb (or maybe even 50mm?). I don't know, because the cutouts were slightly larger than a 48mm apeture. I had to cut some of the area around the bolt holes to allow the plate to fit on the Weber 45's.

The plan all along was to still use very long velocity stacks and figure out a way to attach them to the backing plate. Unfortunately, this proved harded to solve than it seemed. Originally I wanted to try and tack weld the plate to the stacks, but it made little sense. If I welded the front lip of the plate to the front of the stacks, I felt like any benefit of the round lips might be compromised. What I really needed was to fit the plate an inch or two back from the front of the stacks, and make everything air tight.

Again I found an Australian company called Racehead Engineering (RHD) that does some nice fuel injection stuff. They had a 45mm to 48mm velocity stack "extender". Got to be honest, I had no idea what these were supposed to be used for, maybe like a extension between a custom DCOE/DHLA bolt pattern intake on a fuel injected car, but immediately I saw exactly what I needed.

I would bolt the RHD "extenders" on the carbs, then the plate to the ends of the extenders, then bolt a set of short length 30mm trumpets to the front of the plate. That way, I get an effective length of 4"+ on the stacks, and the airbox itself sits neatly on the ends of the stacks. Since the Pipercross 600 is only really about 55mm tall, it can't really accommodate anything but stubby stacks. With the 30mm stacks and the 80mm RHD extenders, it's perfect. Clearance to the wall of the pipercross from the aperture of the stacks is a little over an inch.

One thing I have been reading about Weber and Dell sidedrafts and "lopey" big cams, and how they have a tendency to cause reversion. It makes sense, and it cause some issues with sneezing and general grumbling. I read in Des Hammil's book that sometimes reversion plates were fitted in Shelby cobras and GT40's etc. I did an experiment several months ago where I put a plate in front of the naked stacks to see if it made a difference, around 1.5" inches from the mouths. It did seem to stop some popping and sneezing here and there.

So the theory is now I have a pretty decent reversion plate at the front of the stacks again in the airbox wall, let's see if it makes any difference.

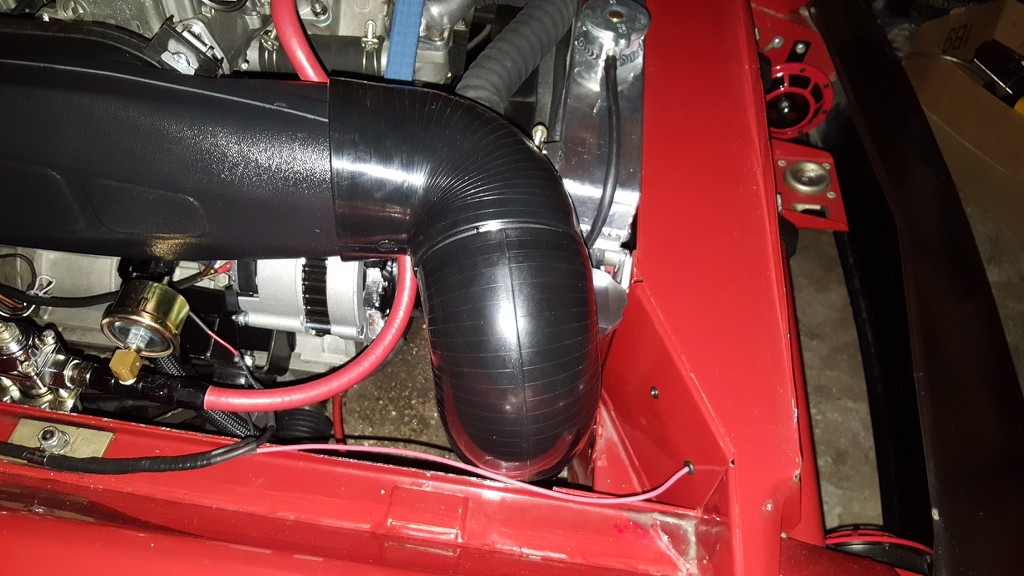

Part II tomorrow, the plan is to use a round aluminum canister style universal cone filter cold air intake in front of the Pipercross 600 airbox, sitting where the stock coolant expansion tank used to be. Had to get a custom coolant expansion tank that was really long and narrow, arond 3" in diameter so the 4" hose could get through there.

The nice things about an airbox (with cold air intake):

1) Decent filtration off a K&N cone cotton gauze filter

2) Stack mouths undisturbed

3) Now I can run my oil catch can (which collects from crank and top of valve covers) into the box, which should tidy up the gassy and oily smells I have been getting with the direct vent setup

4) Cold air right from the front bumper

5) I little bit (I am hoping) of a ram air effect pressurizing the air box slightly at high speeds

6) Dipstick readily accessible

7) Distributor is accessible without removal of anything

Cheers, hope this works, more soon................

Stacks Mounted:

Airbox half on:

Airbox mounted:

Stack airbox clearance:

Some ideas about the routing into the cold air intake:

The ultra slim polished stainless coolant overflow:

Last edited on 07-19-2020 10:09 am by discogodfather